EDM Wire

High Performance EDM

Excellence and Reliability for Industrial Electrical Discharge Machining

With consolidated experience in the melting of binary and ternary alloys (copper, zinc, tin, nickel, silver) and the exclusive use of high-purity metals (999.9/1000), we position ourselves as a strategic partner for the most demanding wire EDM applications.

Our state-of-the-art facilities and rigorous process controls allow us to guarantee superior quality wires, capable of meeting the industry’s highest standards.

The optimized crystalline microstructure of our alloys, the result of accurate casting and precise metallurgical treatment in every production phase, ensures wires with consistent performance, capable of maximizing cutting speed and optimizing energy consumption, even in complex operating conditions.

The excellent surface finish and meticulous straightness of our wires facilitate precise and reliable automatic threading, contributing to superior efficiency in the EDM production cycle, with evident benefits in terms of energy management. The adoption of electronically controlled winders with precision layering guarantees impeccable and constant unspooling across the entire range of available diameters, a crucial element for uninterrupted production cycles.

Tailored support

Our approach is artisanal in every way: in our gestures, in the details, but also in the way we build relationships. We believe in projects born from dialogue, without automatic processes or filters. Do you have a request, a doubt, or a proposal? Contact us.

Solutions

Our Wire Solutions for EDM

We propose an expanded range of wire solutions developed to respond precisely to different production needs, from standardization to niche applications requiring maximum accuracy and performance.

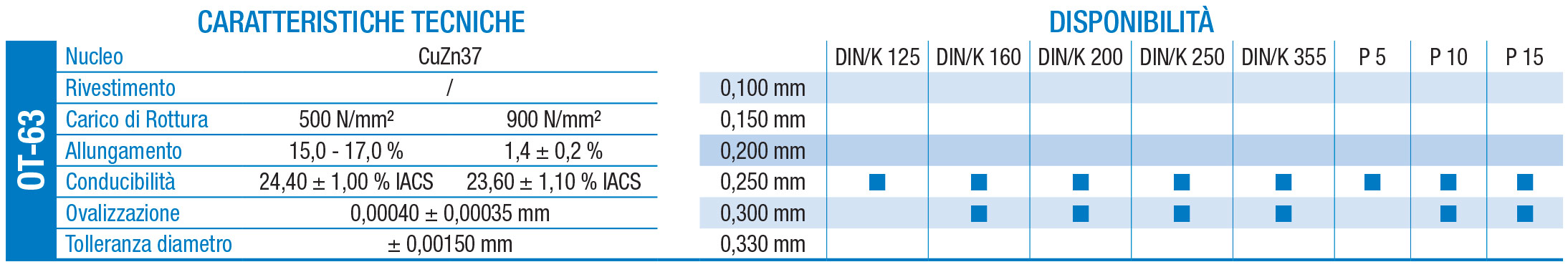

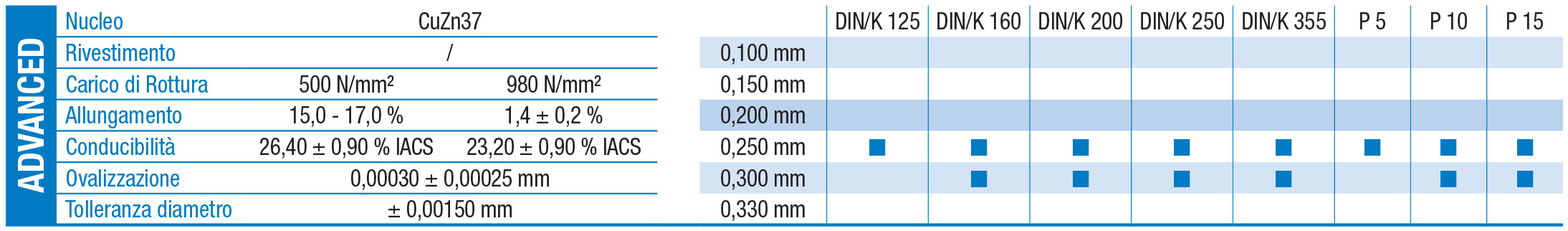

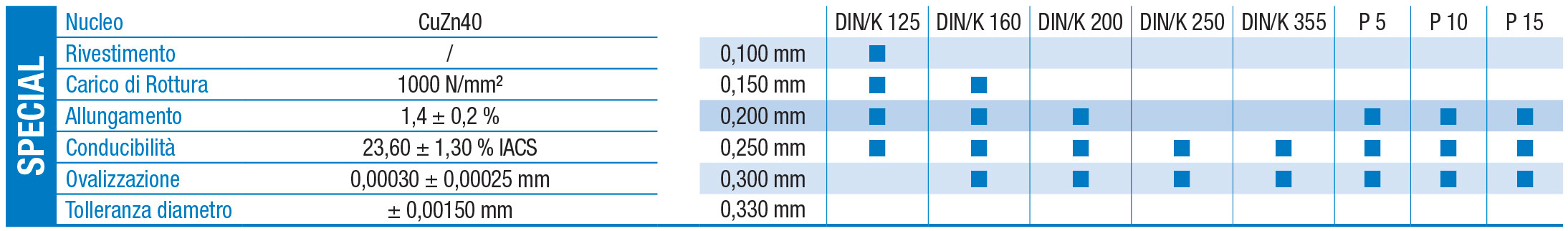

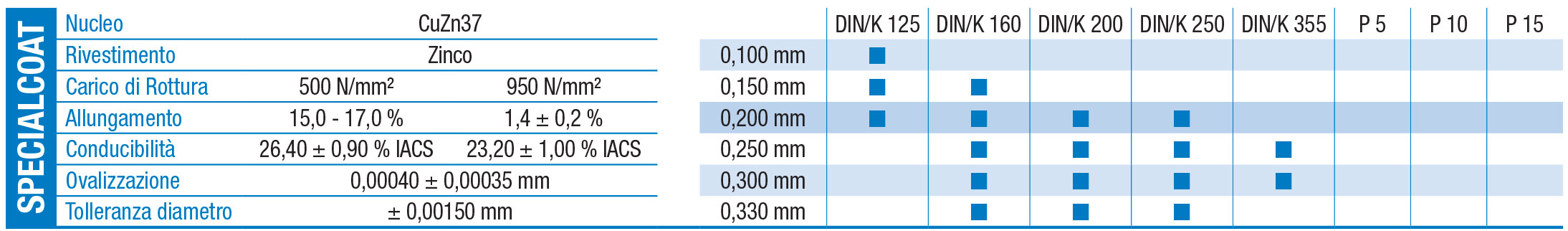

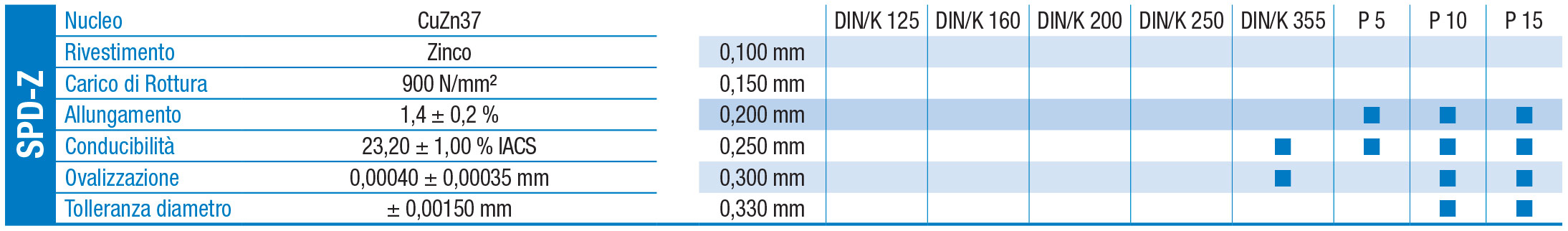

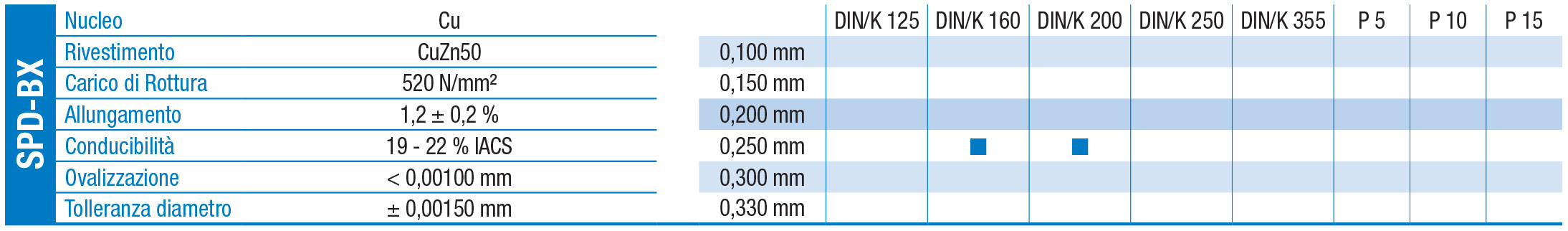

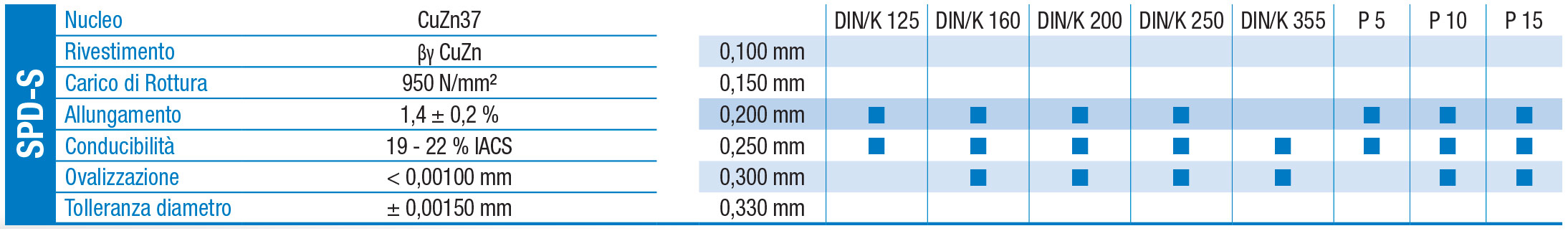

All our EDM wires are available in a diameter range from 0.10 mm to 0.30 mm, with standard tensile strengths of 500, 900, and 1000 N/mm². Customized tensile strengths can be supplied upon request to adapt to specific application needs.

The wires are distributed on spools compliant with German (DIN100–DIN125-DIN160-DIN200-DIN250) and Japanese (P5-P10-P15) standards.

To complement our offer, we provide a complete range of EDM filters, ion exchange resins, spare parts, and equipment essential for optimizing the EDM process.

01 01

Bare brass wire, paraffin-free, conceived for standard operations requiring reliability and consistency. It stands out for an excellent quality/price ratio, making it an efficient choice for daily operations.

02 02

Bare brass wire, paraffin-free, produced with latest-generation technology. It offers extremely high precision, superior surface finish quality, and allows for extremely reliable automatic threading, guaranteeing continuous production cycles (24/7).

03 03

Bare brass wire, paraffin-free, also developed with advanced technology. It ensures excellent precision and surface finish, with automatic threading capability and support for 24/7 production cycles. Particularly indicated for cutting high thicknesses, where it guarantees high processing speeds.

04 04

Brass wire with zinc coating, made entirely in our plant via a latest-generation galvanic line. Specifically suitable for cutting hard and sintered metals. It ensures high cutting speeds, maximum precision, and excellent surface finishes, as well as guaranteeing reliable automatic threading. This wire is particularly indicated for AgieCharmilles EDM machines.

05 05

Brass wire with zinc coating, also produced internally with a latest-generation galvanic line. Ideal for cutting hard and sintered metals, it guarantees high cutting speeds, maximum precision, and excellent surface finishes, with the certainty of automatic threading. Specifically indicated for Sodick, Mitsubishi, Makino, and Fanuc EDM machines.

06 06

High-performance copper wire with an innovative zinc-enriched brass coating. Allows for precision cuts that can be up to 50% faster compared to a standard brass wire. This solution is particularly suitable for AgieCharmilles machines.

07 07

Our top-of-the-range wire, characterized by a special coating and beta-gamma diffusion metallurgical treatment. It offers speeds 30% superior to normal brass, maintaining maximum precision and excellent surface finishes. It is a versatile solution, indicated for all EDM machines.

Technical characteristics and availability

Wire for Industrial Electrical Discharge Machining

Packaging and Protection

Guarantee of Integrity and Performance

To ensure the maximum integrity and reliability of the supplied product, all our wires are wound exclusively on premium ABS spools.

his engineering solution guarantees superior mechanical stability, minimizing the risk of accidental breakage due to impacts or thermal variations, even in the presence of considerable pressure exerted by the wound wire.

Every single spool is meticulously protected with a sheet of paper and subsequently vacuum-packed. This critical process is fundamental to preserving the quality and physical properties of the wire even during prolonged storage periods. Finally, the spools are housed within robust cardboard boxes, guaranteeing optimal protection and greater safety during all handling and transport phases.

Technical characteristics and availability

Wire for Industrial Electrical Discharge Machining